How green tea is made

Miina SaakHow to produce tea from a fresh tea leaf so that it ends up as a cup of steaming hot green tea? And why should you even care how your tea is made? Although processing tea is a bit like making apple pie- every chef has their recipe and all the variations can be amazing, depending on the mood, season and sort of apples, there are still some basics, that we have figured out during our short career as tea makers in Georgia. Knowing how the products end up on your table is an important part of making conscious good choices for yourself, so we feel that knowing what is the process behind making tea, is as important as knowing that milk comes from a cow or carrots grow in the ground :)

EVERYTHING STARTS FROM THE FIELDS

The very first and the most important thing while making teas 100% from Camellia Sinensis is plucking and taking care of the plantations. Since all the tea that we produce in Renegade Tea Estate consists of only the material gathered from the plantations (we do not add any additional tastes or aromas), the quality and agricultural practices have an enormous influence on the outcome. But as the science that goes on in the plantations is a whole bigger topic, today we will cover all the procedures that happen after the leaves have arrived into the factory.

1. WHITERING

First, the tea leaves are spread on a bamboo tray to wither for a few hours. This gives the leaves some time to balance out the enzymes, but withering time, in this case, should be short enough so that the leaves will not start to oxidize. This process is also called “resting time” - so that the leaves can rest from the stressful experience of being subtracted from their mother plant.

As a side note, if you are getting confused with all the procedures, we also have a tea dictionary HERE.

2. FIXING

After a short break on the bamboo trays, the next step in making high-quality green tea is fixing - leaves will roll a few minutes in the high-temperature drier. This quick procedure stops the enzymes in the leaves and prevents the leaves from further oxidizing. This gives the tea it’s fresh green looks and the vegetal taste. If the oxidizing process is done correctly the leaves should be evenly green even after steeping- check it out when you brew loose-leaf green tea the next time!

3. ROLLING

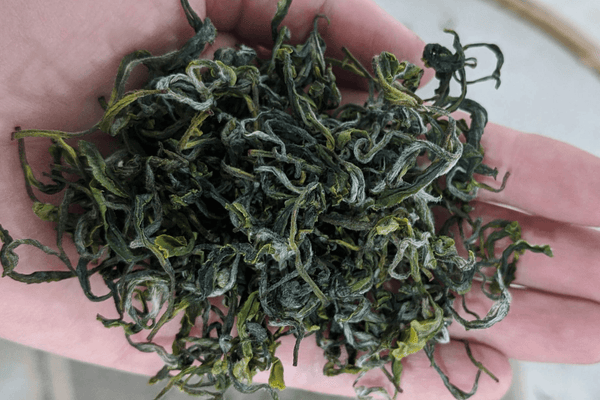

The third step of producing green tea is rolling the leaves into a beautiful shape. Rolling also helps to get the juices flowing in the leaves to get the best tastes out. This procedure takes about 30 minutes.

3. DRYING

Finally, the processed leaves of Camellia Sinensis will end up in a big drying machine, to get the moisture out of the produce and to ensure that the tea will stay good in the package for a while (usually teas should last about 1-2 years). Any moisture in the tea can evolve into different funguses in the tea later on, so this is one of the most important steps. This is why it is also important to store your teas in a dry place where air does not get to it!

And after a few hours of drying there, you have it- great green tea, ready to be enjoyed! The full production circle should last about 4-5 hours, so the leaves plucked in the morning can easily end up in a teacup already in the same evening!

PS! Once you start brewing your green tea, keep in mind that you should never pour boiling water over green tea! The perfect temperature is usually somewhere around 75°C (170°F). If you don’t have a thermometer close by, just hold your hand over the water and if it is warm, not hot, it should be the perfect time to start brewing :)